|

www.endoscoperepair.com

*F.A.Q. Complimentary Endoscope

Information and Inspection Procedures! F.A.Q. +Museum!

+

Visit our Endoscopy Museum below!

( Warning: Graphic

endoscopy photos )

BASIC VIDEO ENDOSCOPE R.G.B.

SYSTEM

Click here

for

Endoscope Specifications!

*Inspection

Procedures for Most Flexible Endoscopes:

Purchase a full comprehensive training video

on Inspecting any endoscope!:

SPVTIP-VHS...Olympus®,Pentax®and

Fujinon® Inspection Procedures

TRAINING TAPE......$50.00

| *Flexible

Endoscope INSPECTION PROCEDURES |

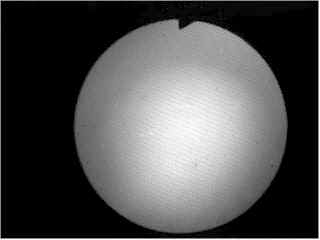

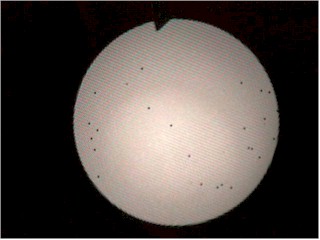

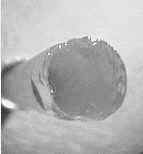

( black dots )

HOW TO CHECK FIBERSCOPES FOR BROKEN FIBERS!

HOLD TIP OF SCOPE UP TO A

LIGHT, LOOK THROUGH EYEPIECE AND FOCUS.

ABOUT 24 BROKEN FIBERS, BLACK DOTS...

THIS SCOPE IS PERFECT, NO BLACK DOTS!

1) View the image: If fiberscope check

for: Broken fibers,

( black dots).

Observe if any signs of fluid invasion;

Stains, "Redcrack", X-Ray yellowing, image brightness etc.

Also view eyepiece for dust, fluid contamination etc.

If checking a Videoscope; Put endoscope

in processor, observe image for signs of fluid invasion (

foggy ) and picture break-up, ( angulate the scope by turning

knobs). If Image is stained, redcrack

repair will be required. If video picture has interference, a

Major Fluid invasion or CCD repair is needed!

How Fluid Invasion

Problems Occur;

- If a scope has a leak which is not detected and the

scope comes in contact with any fluid, moisture will enter

the scope through the leak.

- In fiber scopes, the scope will have major fluid

invasion if the scope is immersed with then ETO venting cap

on. For video scopes, the water proof cap must be attached

before contact with any fluid.

- If a scope has a fluid invasion and is not repaired

immediately, video chip damage and image staining can

result, as well as corrosion of the internal metal

components.

Remember - fluid problems are a scopes worst enemy!

How Image And Light Guide Problems Occur;

- Buckles or bites in the insertion or light guide

tubes can break image and light guide fibers.

- Fluid invasion can cause staining of the fibers,or

video chip damage, if not repaired immediately. The fluid

also causes brittleness of the fiber bundles.

|

2) Plug Video scope into processor, test

#1 , 2,3,4 Freeze frame buttons. If

there is fluid invasion, buttons will either not work or cause

constant freezing and beeping of Processor and will require

replacement...

|

3) Observe Light guide illumination

bundle by observing image, then unplug scope from light

source, hold distal tip to a light and be sure it is not over

%10 broken.

If over 10%,

Illumination bundle will require replacement...

- Pulling on the insertion or light guide tube, as well

as dropping the scope, can cause broken fibers or damage to

the video chip.

|

4) Test Air Leakage: use a air leakage

tester and pump p endoscope with air: waiting 3 minutes @ 3.5

kg/cm2

Submerse endoscope in water and

angulate endoscope to check for small leaks in bending rubber,

insertion tube, light guide tube, body etc

If leaks are found

anywhere on endoscope, this may cause Fluid invasion, and

endoscope will require Aeration immediately!

How Bending Sheaths Become Damaged;

- Any sharp objects like instruments, fingernails or

bites can cause tears or holes in the sheath material.

- Over time, normal wear or over inflation can cause

stretching or looseness of the bending rubber material.

- If the ETO cap is not in place during the ETO gas

sterilization process, the scope will pressurize and the

bending sheath will explode like a balloon. Follow the

instructions on the white card attached to the ETO cap.

|

5) Test Air Water functions: With

Endoscope plugged into light source or processor, and

depressing air/water valve; water should spray out of nozzle

over objective lens at least 30 cc's in 30 seconds, holding

finger on air valve; 50cc's in 5 seconds using a measuring

beaker...Water should shoot over objective lens. Be sure

nozzle is not missing. If air or water

is faulty or missing, air/water nozzle or channels will

require unblocking or replacing...

How Air/Water Problems Occur;

- Scope is not cleaned immediately following procedure.

- Nozzle is damaged, ,missing or misaligned.

- Glutaraldehyde buildup from chemical disinfectants

can break away from the channel and clog the air/water

nozzle.

|

6) Test suction by connecting endoscope

to suction pump and with suction on, depress suction valve

with tip in 80cc of water, endoscope should allow 80 cc's in 5

seconds. If a groove is worn in suction

port, suction will be decreased and will require

replacement...

|

|

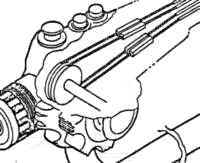

7) Using the correct size Biopsy Forceps, pass the

Forceps through the endoscope biopsy channel and text for

kinks in the channel. Angulate endoscope while passing through

distal end of scope. If forceps do not

pass or resistance is felt, channel(s) may require

replacement...

Biopsy Channel Damage Is Usually A Result

Of:

- Kinked, damaged or open Flexible Endoscope biopsy

forceps can cause tears in the channel material.

- Buckling of the insertion tube can also cause buckles

in the channel.

- Forcing instrumentation through the channel can cause

wear or tears in the channel material. This frequently

occurs in the bending section when resistance is met when

the scope is angulated. Do not pass anything through the

bending section with the tip is angulated further than 110°.

|

|

8) Using the correct size cleaning brush, remove suction

valve and pass through suction port till it is visible at

suction port on connector, if any

resistance is felt, suction channel will require replacement!

|

( represents bad buckles @ boot )

9) Check Insertion tube; look for any holes ( as in step

4 will show leaks). Check for wear, wrinkled, blistered,

buckles etc. Be sure that IT is not impacted, loose and

twists@boot! If buckled @ boot, or

anywhere on tube, insertion tube will require replacement!...

|

|

10) Check angulation; refering to manufacturers

specifications,using angulation chart; angulate endoscope.

Example: CF-100L: Up: 180°, Down

180°, Right 160°, Left 160°. Endoscope should angulate

smoothly with no play. If angulation is

tight or doesn't angulate at all,play and angles will require

adjustment or angulation wire replaced. If bending section

bends irregularly or to one side, bending section mesh or

articulating section will require replacement...

Angulation Problems

Are A Result Of:

- The angulation wires can stretch and break if the

angulation is forced.

- Buckling of the insertion tube can also stretch and

break wires.

- Play in the angulation control knobs usually

indicate an angulation adjustment is needed.

|

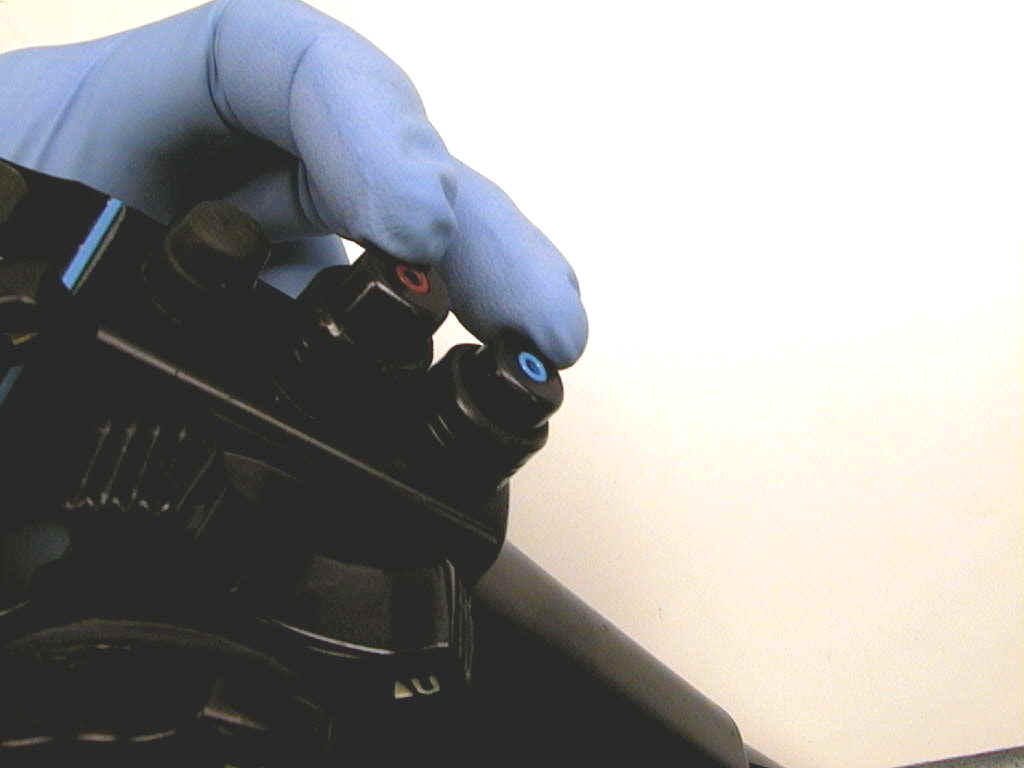

| 11) Check

Knobs, turn knobs back and forth. If they leak are loose or

cracked. They will require replacement.

If a grinding feeling is noticed on Pentax® or Fujinon®, drum

wire will require replacement.

|

|

12) Check the Light guide tube (umbilical), and

connector. Be sure there are no leaks,( as in step 4 will show

leaks), buckles or wrinkled etc. Be sure connector has no

loose parts, fluid in video connector etc. If

it has a leak, buckled or impacted, replacement is required!

|

13) Observe

the distal end,

the

"c-cover" distal and cap should be round and smooth. Check

lenses, they shouldn't be cracked or dirty. Also the same for

objective lens. Check Biopsy channel hole, should be round and

smooth. If C-cover is impacted; cracked,

will require replacement. If lenses are cracked, they will

distort light and will require replacement. If biopsy channel

is cut with laser, c-cover or channel will require repair. the

"c-cover" distal and cap should be round and smooth. Check

lenses, they shouldn't be cracked or dirty. Also the same for

objective lens. Check Biopsy channel hole, should be round and

smooth. If C-cover is impacted; cracked,

will require replacement. If lenses are cracked, they will

distort light and will require replacement. If biopsy channel

is cut with laser, c-cover or channel will require repair.

|

14) Duodenoscopes: Elevator wire check. With forcep down

channel and pointing out of distal end approximately 1 inch,

move Control arm lever, forcep should move up and down at

distal end and observing image, should come into field of view

at manufacturers specifications. If

lever doesn't move elevator wire or is tight or stuck,

elevator wire or lever assembly must be repaired or replaced. |

WIRING DIAGRAMS FOR VIDEO SYSTEMS INFO!

F.A.Q.

Q: How often should endoscopes be checked

for maintenance? Are there generally blatant signs when a

scope is not working properly and should be checked?

A: Scopes should be leak tested after

every procedure and before disinfection. The most effective

leak test is to submerse the entire scope and follow orignial

equipment manufacturer (OEM) instructions. If a leak is

detected, the scope needs to be sent in for repair

immediately. Scopes should be checked for maintenance on a

weekly, monthly, or quarterly basis depending on the number of

scopes used and procedures performed.

There are blatant signs that a scope

should be checked. One of the most common is when a video

scope starts taking pictures by itself, or when it will not

take pictures. Usually this is a sign of fluid invasion. The

fluid has entered the video switch block controls and the

scope needs to be sent in for repair immediately. If a picture

is cloudy on a video scope, users should look for a buildup of

gluteraldehyde on the distal lens. If there is a buildup or

debris on the lens, clean the lens with a rubbing alcohol

wipe. If there is no buildup or debris on the lens, the video

scope probably has fluid in the distal end. The scope needs to

be sent in for repair immediately.

If a fiber optic scope is cloudy, look

for a buildup of gluteraldehyde or debris on the distal

lenses. If there is no buildup or debris, look for fluid in

the eyepiece and distal lenses. If there is any sign of fluid,

send the scope in for repair immediately.

Other signs are clicking and/or

sluggishness in the angulation controls, significant movement

of the insertion tube when angulating the distal end, poor

light transmission, color fluctuations in the video image,

blockage or friction when passing a brush through the biopsy

and/or suction channel, poor water and/or air flow, poor

suction and tears or significant dents in the insertion or

light guide tube. Users should call their repair company

and/or sales representative for inspection and/or advice.

Another sign is fluid in the water

resistant cap when it is removed after the disinfection

process. If fluid is present, redo the leak test. If the leak

test is negative, more than likely the water-resistant cap is

not so water resistant. Leak test the water resistant cap.

Scopes should be checked for rough edges,

sharp nozzles, and cracking/deteriorating glue as all of the

above can pose a significant risk to patient safety.

Q: What are the most common repairs made

to endoscopes?

A:

|

Air/Water nozzle unclog and/or

replacement |

|

Bending rubber replacement |

|

Angulation adjustment |

|

Biopsy channel replacement |

|

Suction channel replacement |

|

Minor fluid invasion (typically the OEM

deems fluid invasion to require a major overhaul). |

|

Major fluid invasion |

Q: What services should endosuite

managers be looking for in a company that offers to repair

scopes?

A: Honesty, , and customer service! Scope

repair companies should be able to tell you why a repair is

necessary. Test your repair company. Tell them you suspect a

scope has a major fluid invasion, send it in for repair and

see what they quote. If you are going to experience the cost

savings of using an independent service organization, they

must be honest. is equal to honesty. Check out the of their

replacement parts. Without , pricing and turnaround time mean

nothing. Last but of great importance as well is customer

service. Everybody makes a mistake once in a while. How does

the lab honor a warranty? Do they continually look for reasons

to charge more money for their mistakes? The following are a

couple good questions to ask:

|

Who does the repairs? |

|

Where do the repair technicians receive

their training? It is good practice to know who is actually

doing the repairs. This allows the endosuite managers to

speak directly with technicians in case of immediate need

for communication. |

|

How are the technicians paid? Do they

receive a percentage of their billings? *What is their

turnover? |

What parts are used in the repair

process? Specifically, what type of bending rubber glue is

used? Some companies use glues.

|

What type of replacement biopsy

channels are used? Ask to see the biopsy channel. Some of

the biopsy channels being used are high but some are of very

poor . Variations in can cause premature kinking and are

more susceptible to puncture via biopsy forceps or cleaning

brush. |

|

What type of replacement suction

channel is used? Ask to see the suction channel. Is there a

spring wrap at each end of the suction channel to avoid

premature kinking? Check out the of Teflon used in the

channel. Variations in can cause premature kinking and

possibly more susceptible to puncture from a cleaning brush.

|

|

What is the process for repairing the

bending section mesh covering the bending section? Ask to

see the mesh and the different sizes available. Is the mesh

replaced or is Teflon tape used to bandage the mesh? Teflon

tape can affect the movement of the bending section that can

cause a variety of problems. |

|

What type of replacement insertion

tubes are used? Is the insertion tube manufactured with a

dual opposing flat coil spring? If the insertion tube is

overly Flexible Endoscope or flimsy, it may have one flat

coil spring. This can cause a variety of mechanical problems

as well as physician complaints of the scope being too

Flexible Endoscope . Does the coating hold up against

cleaning and disinfecting? If the insertion tube is not

coated/protected properly, the insertion tubes can

prematurely leak, split open, and/or buckle. The same

questions apply for the light guide tube. |

|

Does the company support the recoating

and/or retubing of insertion tubes? Metal components of the

insertion tube tend to wear with use. If the tube is

recoated toward the end of the insertion tube life cycle,

mechanical problems may develop. This defeats the investment

of the repair. |

|

What type of replacement light guide

lenses are used? Ask to see the light guide lenses. Is the

entire assembly replaced or is the top lens replaced or is

optical glue used to replace the lens. Poor lenses and/or

repair can cause the light to spray improperly producing a

dark image while inside the patient. This can be construed

as a bad video chip. |

|

Does the company repair video chips?

Ask to see the video chip. If they repair the video chip,

ask about the process. Ask about the warranty? |

|

Loaners! Does the company provide

loaners? Ask to see their loaner inventory. Ask about the

availability of loaners. |

|

Ask to see their repair facility. Meet

the technicians. Meet the repair staff. Ask as many

questions as possible. A good repair company has nothing to

hide! |

|

Ask about the number of repair

technicians and the number of scopes repaired. |

|

Ask about the number of customers they

have in the market place. Sometimes more means less. Repairs

take time. The larger the volume of scopes being repaired

may mean there is less time spent on each scope repair to

insure high . |

Q: Are some scopes more fragile than

others? Are there any brands known within the industry that

generally require more repair than others?

A: Small diameter fiber optic scopes are

more fragile than other scopes.

Special protection should be used during

storage and transport.

Each brand of scopes has advantages and

disadvantages. For liability reasons, We cannot mention a

particular OEM, but managers should look into the warranty and

what kind of support they will receive after the purchase. If

they are buying used equipment, make sure the company has

their own repair capabilities. Some scopes are made to last

and others are what we call resposable scopes. They are not

made to be worked on. Once they break they typically require a

major overhaul by the OEM. This defeats the purpose of buying

a less expensive scope.

Q: If a scope is treated ideally, how

long is the expected lifespan? How long should endonurses and

technicians expect to be able to trust a scope that has been

repaired before worrying about sending it in again?

A: Ideally a scope can last quite a long

time but the life span depends upon the number of procedures

and the number of scopes used to perform those procedures.

Obviously an account with a sufficient number of scopes to

meet the procedure volume will experience a greater life span.

The lifespan also depends upon proper handling, use, care, and

maintenance.

A scope is typically not sent in for

repair until it develops a problem. Obviously a scope repaired

with parts and workmanship will last much longer than a scope

repaired with low parts and poor workmanship.

Q: How should scopes be treated to

prevent excessive repair bills?

A: Scopes should be treated according to

OEM specifications. Most nurses and technicians do an

excellent job in the handling of endoscopes. We recommend

having dedicated cleaning personnel. This avoids the number of

people involved in the handling process. Fewer people involved

can reduce excessive repair expenses. Dedicated cleaning

personnel can reduce repair bills by routinely performing

proper cleaning and disinfection procedures as proscribed by

the OEM. Familiarity with the scopes can prevent damage before

it occurs. A technician familiar with the scopes can usually

notice buckles or kinks in the channels and other signs as

listed above that if detected would be a minor repair charge.

Leak testing is by far the most important step in reducing

repair expenses.

|

OLYMPUS®

CLEANING AND REPROCESSING CHARTS CLICK HERE!

INSPECTION PROCEDURES BIOPSY FORCEPS |

| Handle should

open jaws cleanly and smoothly. If jaws

are locked shut, repair of jaws is required. If Handle broken,

replacement required. |

| Observe coil

pipe, they should be smooth and straight.

If bent or twisted, coil pipe

replacement is required. |

INSPECTION PROCEDURES RIGID ENDOSCOPE |

Observe eyepiece section.

If dropped and damaged, eyepiece will

require repair. |

Observe image, should be crystal clear.

If foggy or any specs of dust or dirt,

repair required: ( Eyepiece, rod lens, objective ). |

Observe image, it should be

crystal clear.

If distorted or no image, repair

required: ( Eyepiece, rod lens, objective ).

(

chipped Rod lens ) |

Externally view distal tip of endoscope, check objective

system. If impacted and damaged at tip,

repair required. ( Objective system ). |

Inspect

the metal shaft of rigid

endoscope, it should be straight. If

impacted, bent and damaged at tip, repair required. (

Straighten or replace shaft, rod lenses, possible refiber ). |

Point the tip at a light, observe light post of rigid

endoscope, it should be round and bright with less than 5%

broken fibers. If more than 5% it will

require re-fibering. |

Gastro Links +

Return to Online

Repair Price List

!

7322 Manatee Ave. West #265

Bradenton, FL. 34309 USA

Call or Text : 941 209 8276

1.941.209.8276

* Inspection procedures

are industry wide inspection tests. They may not be Manufacturers recommended

inspection procedures.

|

|